We frequently receive emails from companies seeking advice on manufacturing in the USA. Some want to launch a new product made here. Others want to reshore a product and bring it back home. We love to hear this enthusiasm for making things in America. We've turned to guest writer Millar Kelley, research analyst with the Reshoring Initiative, to point potential Made in USA companies on the right path.

How to Manufacture a Product in the USA

The time is right to make more Made in USA products available to U.S. consumers

Are you considering opening a new company, or moving production from offshore to the U.S.? Changing locations or launching a new product is always a challenge, especially for smaller companies. The challenge is typically to determine whether twenty to thirty small overhead costs make up the difference for higher U.S. manufacturing costs. Hopeful companies first need to accurately evaluate whether their product is right for U.S. production.

Here are some tips to get started. Follow the links for more in-depth discussion.

1. Look at trends in your industry. Research which of your competitors has successfully produced in the U.S. – do their reasons for reshoring and U.S. production seem like they would apply to your product as well?

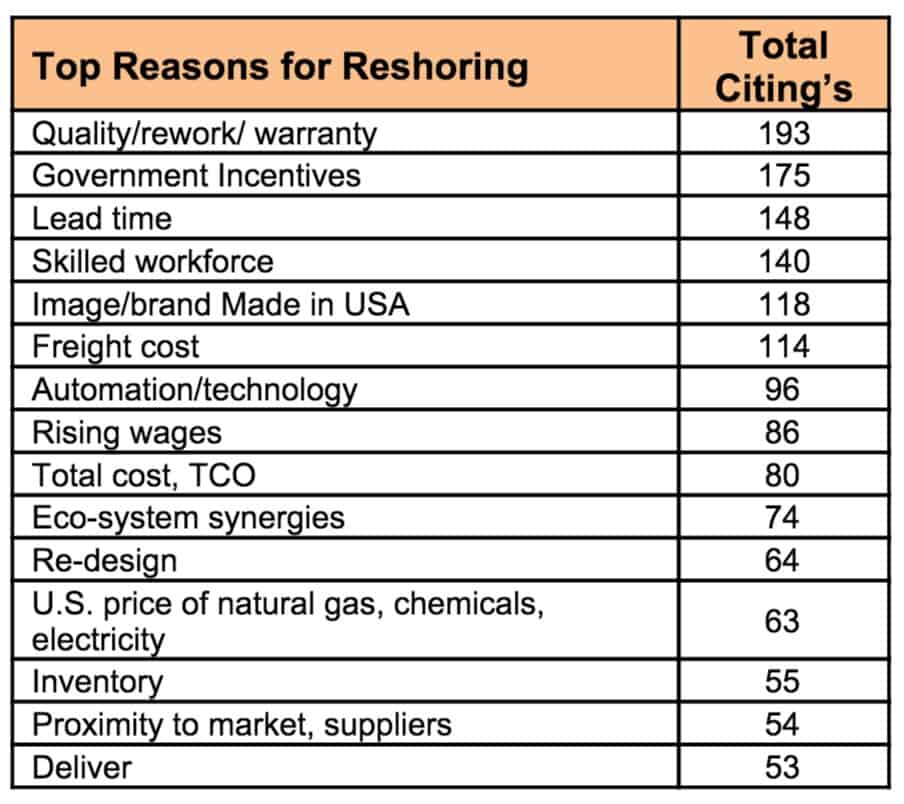

Top reasons for reshoring in the consumer product industry:

Some products will take the best advantage of the consumer preference for Made in USA, including: products for infants, products intended for the affluent, consumers over 60, Midwesterners, and Millennials. Our data shows that having a Made in USA brand was a reason in about 15% of all reshoring cases.

2. Decide if it’s right. To really know if your product can competitively be made in the U.S., you will need to do a Total Cost of Ownership (TCO) analysis of offshore vs. domestic production. If the analysis generates a close call, consider investing more in your own competitiveness with DFMA, lean, and skilled workforce recruitment.

3. Proceed to production. Once you have determined that U.S. production makes sense, you will need to find the best contract manufacturer. There are several organizations that can help such as MEP and ThomasNet.com. Also, give your local Economic development organization (EDO) a call.

4. Enjoy the results! Finally, never forget the end goal: use your efforts to your best advantage by advertising that your product was Made in USA.

- Send out a press release to your local media.

- List your product on Made in USA specific sites, like USA Love list!

- Make sure you advertise your product as Made in USA on all retail distributor sites such as Amazon.

- Be compliant with USA labeling.

These tips and many more are available from the Reshoring Initiative’s Resources for Retail Suppliers.

Contact us if you need help.

Made in America could be more feasible and successful when occupation can co-exist with an industry. Occupation has a skill set that is accompanied by centuries in families or small businesses. Occupations have joy and pride but not competency for the best ROI. A person making keys in Walmart is not a locksmith.

I am trying to say that we did not only lose manufacturing overnight.

We lost our occupations, pride, and culture. I am not making industry or BIG industry a culprit but big manufacturing consolidated and was efficient in performance and ROI.

I believe we were masters and could be First in doing the above very successfully and reaped the sweet fruit. Progression of such was the final nail in the coffin when we had to ship our consolidations overseas. Not doing such would have been more dreadful. The question is why we did not try hard to keep the occupations and consolidations co-exist and then keep both at home. We shipped a lot of pride and lost the souls which were engraved with the pride of such occupations and achievements in respective occupations. How we bring those dead souls to life.

If I am correct, Early macs or Apple products have the signatures of the builder but later such practice was stopped. Again, the point is somebody values pride and marksmanship in occupations even in big industries.

Governments need to do more than budget and red tape because a lot more non-tangible is lost as well.

Hi! Currently, turning on CNC machines allows you to produce parts in large quantities with high accuracy, read more about cncnow. Based on this, the mass production of parts on CNC machines is more preferable than the production of parts on classic lathes

I would like to see USA Love List compile a list of American manufacturers by product category and get it out a few times a year for different products. For example, gifts/clothing/home holiday decor released in Sept., building and remodeling products/appliances/tools and home maintenance released in Jan., outdoor products like grills, pool & patio equipment, recreational items released in April. I would use that to research and plan purchases only from US manufacturers if that was available.

I like the term “reshoring” and I’d like to see more of it. Thanks for posting!

What a great article! You don’t see information like this every day. Thanks for posting!